產品優勢

結構穩定 性能可靠

軸(zhou)承座(zuo)采(cai)用整體式鑄鋼結構,避免兩片式軸(zhou)承室給機(ji)(ji)架帶(dai)來(lai)的不必要負擔,提高整機(ji)(ji)結構的穩(wen)定(ding)性(xing)。此(ci)外重型偏心軸(zhou)采(cai)用鍛(duan)坯進行加工,使PEW系(xi)列顎式破碎機(ji)(ji)具有超凡的可靠性(xing)。

V型結構 齒形護板

"V"型破碎(sui)(sui)腔和(he)齒形護板設計更加的(de)合(he)理,保證實際入料(liao)尺寸和(he)理論入料(liao)尺寸的(de)一致性,有效增大破碎(sui)(sui)面積,物料(liao)在破碎(sui)(sui)腔內(nei)不會(hui)發生堵料(liao),是的(de)破碎(sui)(sui)率和(he)產量(liang)化(hua),提高顎板的(de)利用率。

液壓控制 清腔方便

配備(bei)液壓油站,保(bao)證(zheng)機器潤滑(hua)系統為機器需潤滑(hua)部件供(gong)油,為機器安全作業提供(gong)保(bao)障(zhang)。同(tong)時,如果破(po)碎(sui)機在(zai)負(fu)荷(he)狀態下停機,液壓清腔系統可迅(xun)速清理(li)破(po)碎(sui)腔,大(da)大(da)減少了(le)停機時間。

楔塊裝置 調節快捷

采用楔(xie)塊排(pai)(pai)料(liao)口(kou)調(diao)節(jie)(jie)系(xi)統(tong)(tong),是機器即使在空(kong)轉情況下(xia)(xia)也(ye)可以再幾(ji)分鐘之內把(ba)排(pai)(pai)料(liao)口(kou)挑到預(yu)定值,在液壓系(xi)統(tong)(tong)配(pei)合下(xia)(xia),實(shi)現自動化(hua),比(bi)老(lao)式(shi)的墊片式(shi)排(pai)(pai)料(liao)口(kou)調(diao)節(jie)(jie)系(xi)統(tong)(tong)更簡單(dan)、安全、快(kuai)捷。

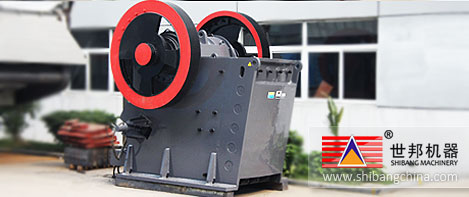

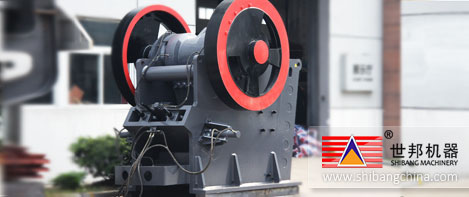

工作原理

電動(dong)(dong)(dong)(dong)(dong)機(ji)驅動(dong)(dong)(dong)(dong)(dong)皮(pi)帶(dai)和(he)(he)(he)皮(pi)帶(dai)輪,通過(guo)偏(pian)心軸(zhou)使動(dong)(dong)(dong)(dong)(dong)鄂(e)(e)前后(hou)上下(xia)擺動(dong)(dong)(dong)(dong)(dong),當(dang)動(dong)(dong)(dong)(dong)(dong)鄂(e)(e)推動(dong)(dong)(dong)(dong)(dong)動(dong)(dong)(dong)(dong)(dong)鄂(e)(e)板(ban)(ban)向定鄂(e)(e)板(ban)(ban)運動(dong)(dong)(dong)(dong)(dong)時,物(wu)料(liao)(liao)被壓 碎(sui)(sui)或劈碎(sui)(sui)。當(dang)動(dong)(dong)(dong)(dong)(dong)鄂(e)(e)和(he)(he)(he)動(dong)(dong)(dong)(dong)(dong)鄂(e)(e)板(ban)(ban)在偏(pian)心軸(zhou)、彈簧的作用下(xia)后(hou)退(tui)時,先前已被壓碎(sui)(sui)或劈碎(sui)(sui)的物(wu)料(liao)(liao)從鄂(e)(e)板(ban)(ban)的下(xia)部(bu)排料(liao)(liao)口排出。隨著電動(dong)(dong)(dong)(dong)(dong)機(ji)連(lian)續轉動(dong)(dong)(dong)(dong)(dong)而破(po)碎(sui)(sui)機(ji)動(dong)(dong)(dong)(dong)(dong)鄂(e)(e)作周期性地壓 碎(sui)(sui)和(he)(he)(he)排泄物(wu)料(liao)(liao),實現批量生產。

請選擇: |

請選擇: |